Main Content

Official proposal

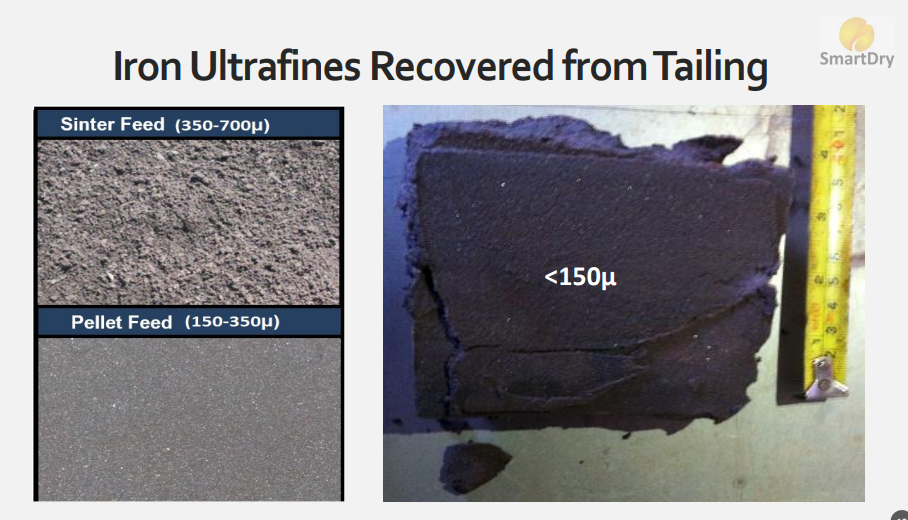

Tailings are the left-over materials from the

processing of mined ore. They consist of ground rock, unrecoverable and

uneconomic metals, chemicals, organic matter and effluent from the process used

to extract the desired products from the ore. They are stored in tailings

storage facilities and can cause significant environmental impacts if not

properly treated and the mining and disposal area completely recovered.

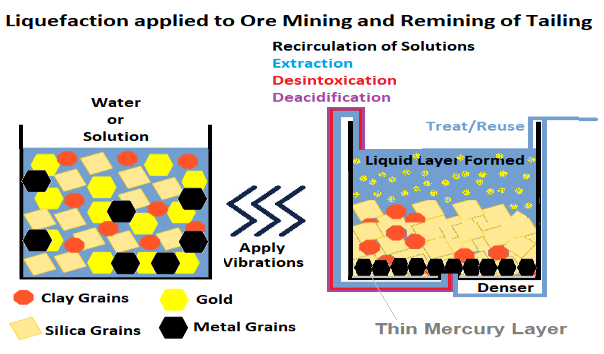

Our proprietary

SmatDry solution for exploring tailings is technology based on liquefaction is

a hardtech with innovative equipments and processes for the metal mining

sector, dewatering, mineral separation and recovery of metal ultra fine grains

from tailings. We can recover valuable minerals from waste at much lower costs

than conventional processes.

How does it work?

Opportunity

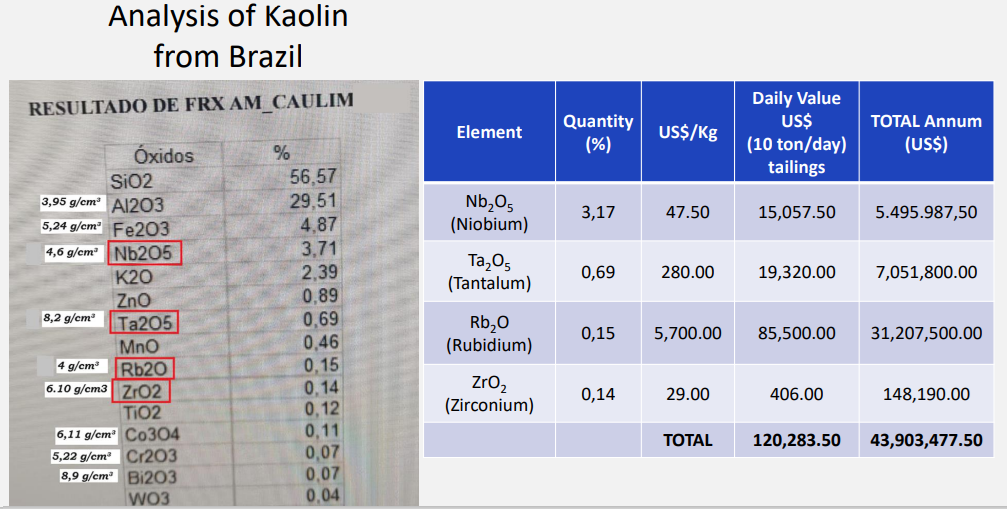

Waste generated by Gem Mining

Volume: 10 tons/day

Waste contains:

Quartz = depending on quality and type can

add value;

Muscovite = KAl2

(Si3Al)O10(OH,F)2 used in engineering

studies;

Tantalite = [(Fe,Mn)(Ta,Nb)2O6] source of

Niobium and Tantalum, commonly

associated with Columbite (Coltan)

3% Nb2O5 (Niobium Oxide) and 3.0%

Ta2O5 (Tantalum Oxide);

Plagioclase = depending on the type, can be of high value;

Pitch - SmartDry Solutions

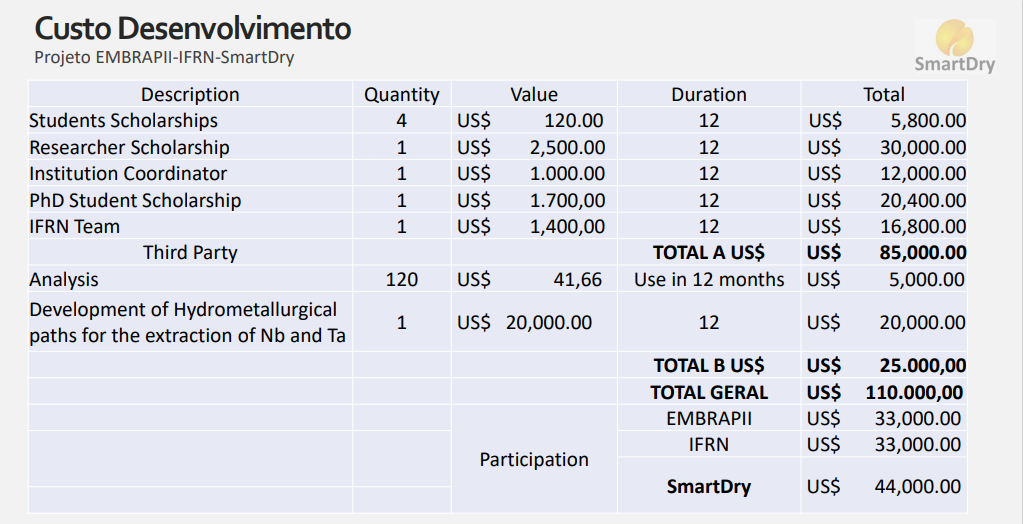

Use of Capital

- Pilot Plants Development

- Recovery/Separation Plant

- Hydrometallurgical Extraction Plant

- Complete Team

- 01 Operational Staff Recovery

- 01 Operational Staff Hydrometallurgical

Extraction Plant

- 01 Sales/Logistics staff